Why Paper-Based QA Checklists Are Holding Back Your Manufacturing Team

If you're still using paper forms to inspect for cleanliness and safety on your factory floor, you're not alone—but you might be falling behind.

In fast-paced real estate manufacturing environments, quality assurance (QA) and compliance teams need to catch exceptions as they happen, not days later. That’s where paper-based audit checklists fall short—and where tools like SimplyParse can make a real difference.

Let’s break it down.

The Hidden Costs of Paper-Based QA Checklists

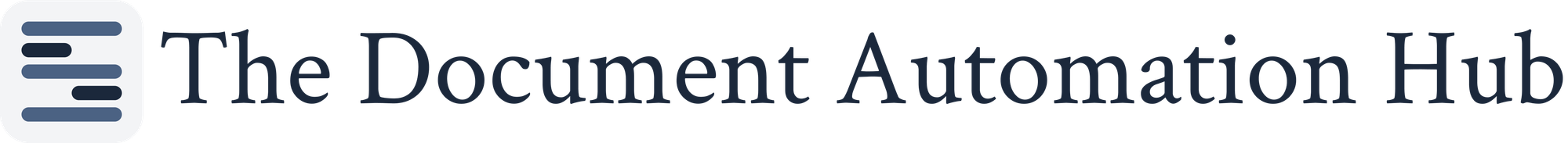

Paper checklists may seem simple, but they’re riddled with inefficiencies. Auditors fill them in manually, and someone else has to re-enter that data later. It’s a double-handling process that drains time and introduces errors.

“Paper forms are time-consuming to manage, easily damaged or misplaced, and difficult to compile into meaningful reports.”

Key limitations:

- Manual data entry: Every form has to be read and keyed in. This eats into admin time across all shifts.

- Limited detail: Paper can’t easily capture rich data like photos or context, leading to incomplete reports.

- Loss and damage risk: Forms can go missing or degrade over time, compromising audit trails.

The Real Risk: Delayed Reporting

One of the biggest issues with paper audits? You often don't find out there's a problem until it's too late.

As one plant supervisor put it:

“By the time we see the paper, the scrap’s already happened.”

When checklists sit in binders or inboxes waiting for review, hazards or failures go unaddressed. That delay can mean increased downtime, compliance issues—or worse, safety incidents.

What goes wrong:

- Lag in visibility: Managers don’t know about exceptions until long after they occur.

- Missed exceptions: There's no real-time flagging. If something is skipped or fudged on paper, it might stay buried until the next audit cycle.

The Solution: Real-Time, Digital Audits

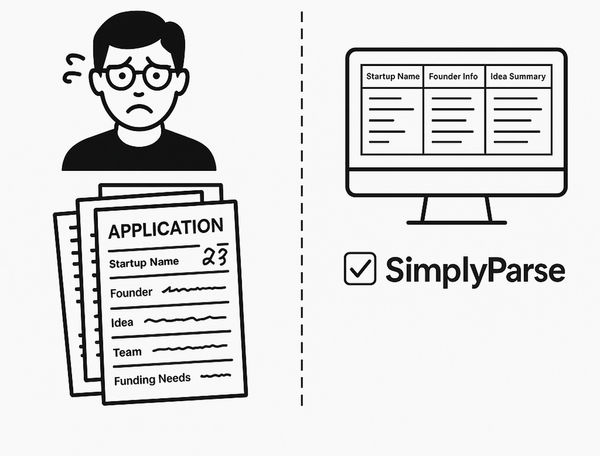

Digital checklists solve these problems by making QA inspections faster, smarter, and more actionable. Tools like SimplyParse can read your standard inspection forms—tick-marked, handwritten, phots, PDFs and scanned copies—and in real time push the necessary details to your system.

The benefit, QA managers get immediate visibility into inspection results in your existing software.

Closing Thoughts

For manufacturers, clean and safe operations are non-negotiable. But relying on paper forms to monitor those standards slows you down and puts your team at risk.

By digitizing your QA audit process and using intelligent tools like SimplyParse, you can respond faster, reduce errors, and ensure nothing slips through the cracks.

Sources:

- “How to Digitize Your Safety and Quality Audits” – SafetyCulture Blog

- “The Hidden Cost of Paper in Manufacturing QA” – Tulip Interfaces

- “Manual Safety Inspections: Why They're Risky in Modern Operations” – EHS Today

Contact:

📧 Email: hi@simplyparse.com

🌐 Website: simplyparse.com