Streamlining the Sales-to-Production Handoff

In many manufacturing businesses, the handoff from sales to production is still a manual, error-prone process. Sales orders often arrive in various unstructured formats — via emails, PDF attachments, phone calls, WhatsApp messages, and even paper forms. These orders then need to be consolidated into spreadsheets or directly entered into an ERP system for production planning. This traditional workflow typically involves multiple touchpoints:

- Order Intake: Sales orders come in through emails, paper forms, WhatsApp messages, etc., often containing varying formats and details.

- Data Re-entry: A sales coordinator or customer service representative manually re-enters or copy-pastes the order data into Excel or directly into an order management/ERP system.

- Planning & Fulfillment: Production planners then use the compiled data to schedule manufacturing and fulfillment.

Each manual step in this process creates opportunities for mistakes and delays. According to a 2023 survey of manufacturers, 82% of companies reported experiencing errors in their order entry process, with an average error rate of around 4.2% (with some companies reporting as high as 7%). These errors, though seemingly small, can quickly add up. The survey indicated that manufacturers lose an average of $500,000 annually due to order entry inaccuracies. Beyond direct financial costs, the ripple effects are far-reaching. 67% of suppliers stated that manual entry causes delays in processing and shipping, and more than half said these delays often lead to missed sales or dissatisfied customers. In other words, a slow or inaccurate sales-to-production handoff can severely disrupt operational efficiency and hurt customer trust. Each error might require costly rework, returns, or expedited shipping to fix the issue — costs that erode profitability. Industry benchmarks suggest each faulty order costs around $18,000 on average when factoring in all downstream corrections and fallout. Furthermore, 85% of B2B customers will reduce or stop doing business after just three order mistakes. Clearly, relying on emailed forms and spreadsheet consolidation is not only tedious but also risky and costly.

The Value of Automating Unstructured Order Inputs

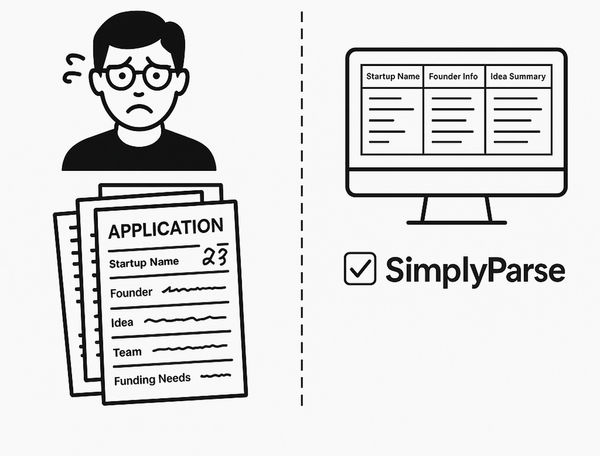

Given the significant costs and risks associated with manual processes, automating the sales-to-production handoff can deliver major benefits. A key advantage of automation is its ability to convert unstructured inputs (emails, PDFs, chat messages, handwritten or printed orders) into structured, production-ready data with minimal human intervention. Many manufacturers struggle with handling these non-standard order formats. In the aforementioned survey, 76% of suppliers said that dealing with orders from emails or low-quality forms was a significant challenge.

The time savings are equally impressive. Instead of waiting for a sales coordinator to consolidate orders into Excel, orders flow instantly into production queues. Integrated automation can reduce order processing times by as much as 75%, accelerating the order-to-production cycle. For example, one precision parts manufacturer cut its order-to-cash cycle from 32 days to just 14 days after adopting an AI-driven order intake system, thanks to the elimination of manual handoffs. Automation also frees up staff from the monotonous task of copy-pasting data. Sales operations teams and customer service representatives can spend more time on value-added activities like customer communication or proactive planning, rather than managing spreadsheets.

Real-World Impact: Time Savings and Error Reduction

Several manufacturing companies have experienced tangible benefits after automating the sales-to-production handoff. One mid-sized industrial manufacturer was experiencing an average 4-day lead time just to process orders internally before production could even begin. They also had a 12% error rate on manual order entries. After implementing an AI-driven, ERP-integrated order automation solution, they achieved an 85% reduction in order processing time and a 95% decrease in data entry errors. As a result, orders that once took days of back-and-forth and corrections were now ready for production in just hours, with virtually no errors in order details. This company also saw on-time deliveries improve by 28%, as production schedules were no longer disrupted by missing or incorrect order information.

Ultimately, automating the intake of sales orders reduces manual labor, minimizes costly errors, and speeds up throughput. For sales coordinators and production planners, this means less time firefighting data issues and more time ensuring orders are fulfilled efficiently. For the business, this translates to lower operational costs and happier customers.

In today’s fast-paced manufacturing environment, investing in automation isn’t just a convenience — it’s quickly becoming a competitive necessity. Moving from a manual, Excel-driven handoff to an integrated, automated process can turn a once error-ridden bottleneck into a streamlined pipeline, transforming the way orders move from the sales team to production, and improving efficiency, accuracy, and profitability.

Sources : doosty.com , conexiom.com , artsyltech.com

Ready to streamline your sales-to-production handoff?

Automate your order processing with SimplyParse and eliminate manual errors, reduce lead times, and improve production efficiency. Book a demo today to see how we can transform your order workflows into a seamless, automated process.

Contact:

📧 Email: hi@simplyparse.com

🌐 Website: simplyparse.com