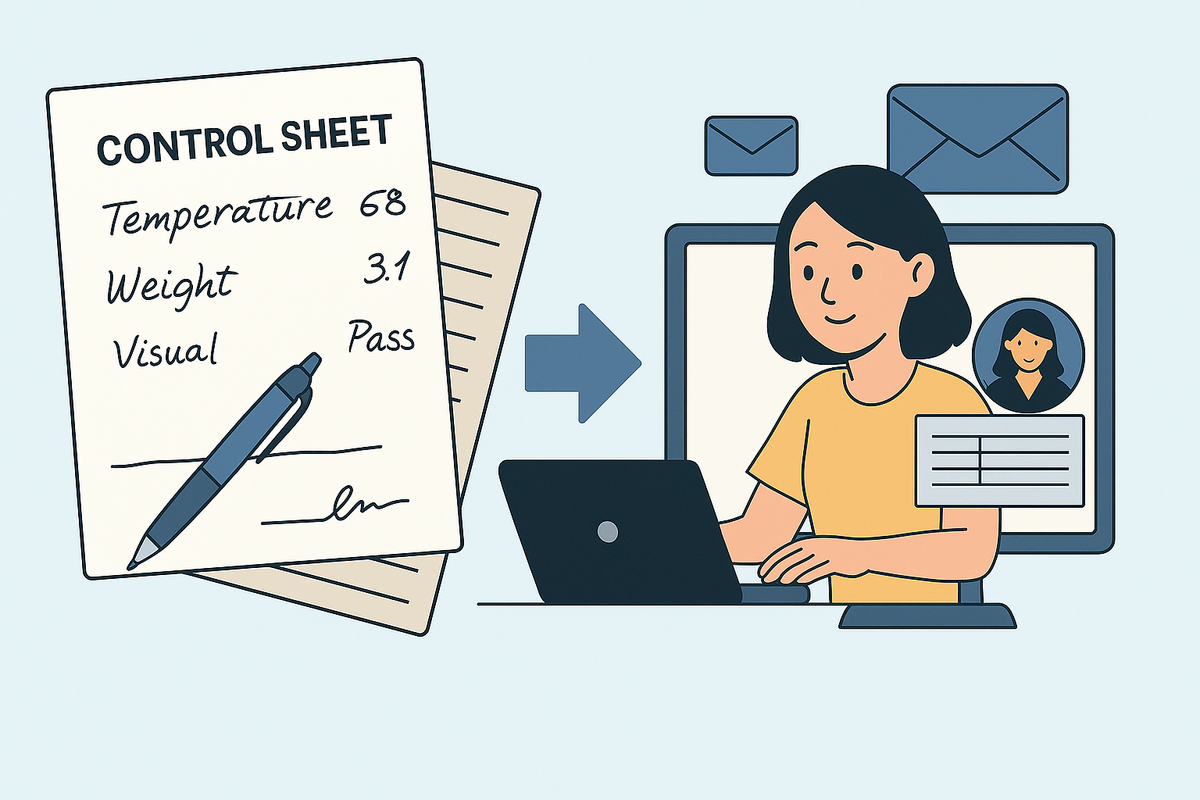

Automating Handwritten QC Data Logging with SimplyParse in Manufacturing

In many manufacturing facilities, Quality Control (QC) teams still rely on printed control sheets to record critical inspection data such as temperature readings, weights, and visual inspection results. While this method has been the norm for years, it brings with it significant inefficiencies that can impact overall production quality.

Manual Logging Inefficiencies

Manual data entry is time-consuming, labor-intensive, and prone to human error. Studies show that 70% of manufacturers still use paper-based QC logs, which highlights the extent of the reliance on manual data collection methods. A typical day in a manufacturing plant might involve recording hundreds or even thousands of data points on paper, which must then be transcribed into digital systems. This duplication of work not only wastes valuable time but also increases the likelihood of data entry errors.

The average error rate in manual data entry is around 1%, which might seem low but can quickly escalate in high-volume environments. For instance, a mistake in recording a critical temperature or weight can lead to batch rejections, costly product recalls, or even compromised product quality. In fact, a product recall can cost a company upwards of $10 million. The manual data entry process also creates a significant time lag between when inspection data is collected and when it becomes available for review, limiting the ability of supervisors to take real-time corrective actions.

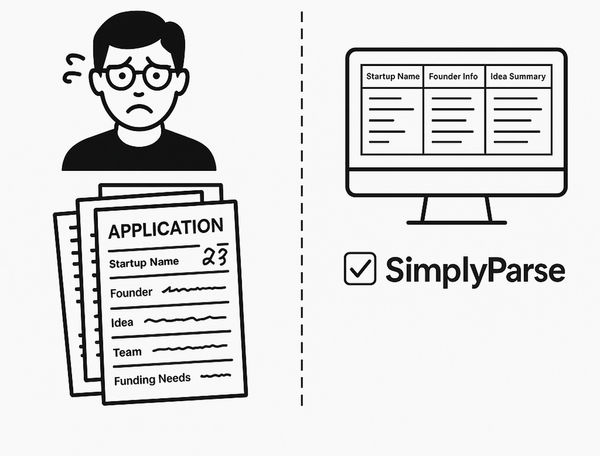

Improved Accuracy

One of the key benefits of automation is data accuracy. With SimplyParse, the typical error rate associated with manual transcription is virtually eliminated. The platform helps with an accuracy rate of 95%, significantly reducing the likelihood of human error. This allows your team to trust the quality data in real-time, ensuring that decisions are based on correct, up-to-date information.

Increased Efficiency

By digitizing inspection data, SimplyParse removes the need for manual transcription, allowing quality assurance teams to process data more quickly. Real-time data capture means that temperature readings, weight measurements, and inspection results can be instantly available to supervisors, rather than waiting until the end of the shift. This improves responsiveness, allowing production issues to be addressed immediately, reducing delays and downtime on the floor.

Seamless Integration with QMS and ERPs

Another advantage of using SimplyParse is its ability to integrate seamlessly with your Quality Management System (QMS) or ERP. SimplyParse can easily connect with systems like SAP Quality Management, Oracle Quality, or Siemens Opcenter. The data captured from handwritten QC forms is automatically structured and transferred into these systems, eliminating the need for duplicate data entry. Whether you use a popular QMS like SAP QM or a custom ERP, SimplyParse ensures that the data flows directly into your existing infrastructure, allowing your team to focus on analysis rather than data entry.

The Benefits of Automating QC Data Logging

The transition from manual logging to automated data capture offers several key benefits:

- Real-Time Data Availability: Automated data capture ensures that QC data is available immediately, enabling quicker decision-making and faster responses to issues on the production floor.

- Enhanced Accuracy and Reliability: SimplyParse reduces the risk of errors in data entry, ensuring that quality data is both accurate and reliable.

- Improved Audit Readiness: With all inspection records digitized, audit trails are easily accessible, making it simpler to comply with quality standards and pass internal or external audits.

- Time Savings: By removing the need for manual transcription and eliminating duplicate entry, SimplyParse frees up time for your team to focus on more strategic quality management tasks.

- Cost Savings: Reducing errors and speeding up the quality process not only improves production efficiency but also cuts down on costly mistakes, such as batch rework or product recalls.

For Quality Assurance Heads and Production Supervisors, adopting SimplyParse to automate the digitization of QC inspection data represents a significant leap forward in operational efficiency. By removing manual entry bottlenecks, improving accuracy, and providing real-time data access, SimplyParse helps ensure that your quality processes are faster, smarter, and more compliant.

As manufacturing environments move toward Industry 4.0, automation in quality control is no longer a luxury—it’s a necessity. SimplyParse enables manufacturers to streamline their QC processes and unlock the full potential of their quality data, leading to improved product quality, reduced costs, and a more agile manufacturing process.

Sources : techtarget.com , oracle.com , plm.sw.siemens.com , domino-printing.com , nam.org

Ready to Experience the Difference?

📞 Book a demo to see how SimplyParse can streamline your quality control process and improve the accuracy and speed of your QC data logging.

Contact Us:

📧 Email: hi@simplyparse.com

🌐 Website: www.simplyparse.com